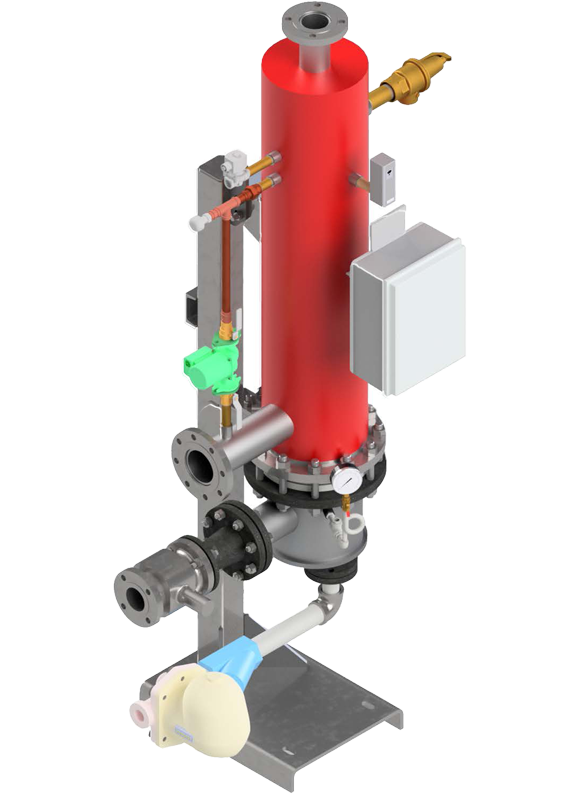

Simcoe Air Source CO2 Heat Pump

- • CO2 Refringent

- • Double Walled Condenser

- • Variable Speed Recip Compressor

- • Air Source Tub and Fin Coil

- • Variable Speed EC Fans

- • Electronic TX Value

- • Electric Defrost

- • Built In Circulating Pump

- • Small Footprint

- With the Simcoe Air Source Heat Pump units, the capacity generates varies with the ambient temperatures. This will result in the capacity generated higher ambient temperatures being greatly increased. If this is not addressed then it will lead to excessive cycling of the compressor which in turn, will lead to greater fluctuation in the system supply temperature.

Severn Water Source Heat Pump

- • Double Walled Condenser

- • Variable Speed Scroll Compresso

- • Air Source Tube and Fin Coil

- • Variable Speed EC Fans

- • Dual Stage/ Circuit - Economizer Vapour Injected

- • Electronic Defrost

- • Small Footprint

- • Service Access

- The Severn unit has a variety of methods to control leaving water temperature (LWT). It allows for staging of the compressors. There is also a bypass loop that controls the LWT, as well as control of the head pressure. Using multiple unit modular system allows for larger installed systems as well as greater turn down.

- The vapour injected scroll compressor will give a large ambient temperature operating range with supply water temperature set point adjustable from 90°F to 180°F. The Severn water sourced heat pump can operate from 30°F to over 120°F ambient temperature.

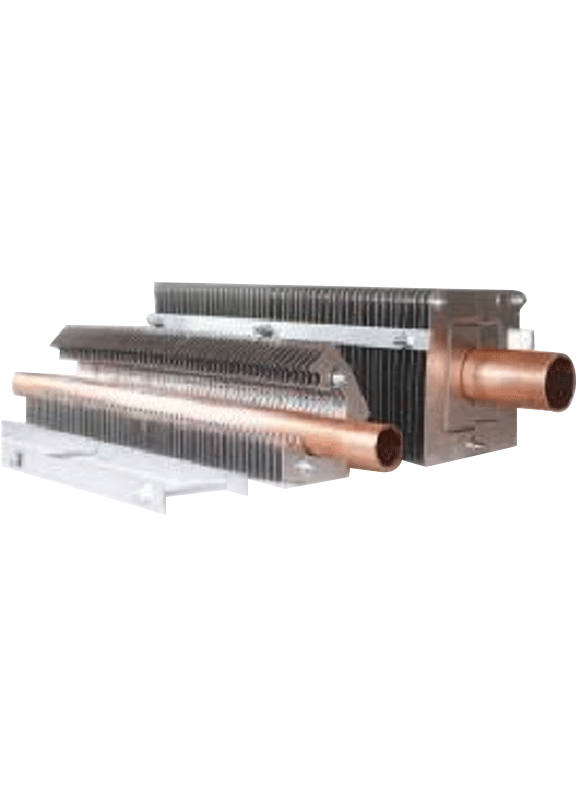

Hatch Air Source Heat Pump

- • Double Walled Condenser

- • Variable Speed Scroll Compressor

- • Air Source Tube and Fin Coil

- • Variable Speed EC Fans

- • Dual Stage/ Circuit

- • Economizer Vapour Injected

- • Electronic TX Valve

- • Electric Defrost

- • Small Footprint

- • Service Access

- The Hatch unit has a variety of methods to control leaving water temperature (LWT). The compressor is DC inverter driven with a wide operating range. This allows the same machine to be applied to a single pass (high ΔT) or multiple pass (low ΔT) without additional adjustment. The unit comes equipped with a variable capacity inverter driven compressor. The compressor is equipped with a vapour injection port allowing the use of an economizer circuit to increase the capacity at low ambient conditions as well as good COP. The unit is also equipped with variable speed fans that will modulate in accordance with the ambient conditions.

- The vapour injected scroll compressor will give a large ambient temperature operating range with supply water temperature set point adjustable from 70°F to 140°F. The air sourced heat pump can operate from -30°F to over 95°F ambient temperature.